23 June 2025

Novel Microbubble Method Achieves 100 per cent SO₂ and Over 95 per cent NOx Removal

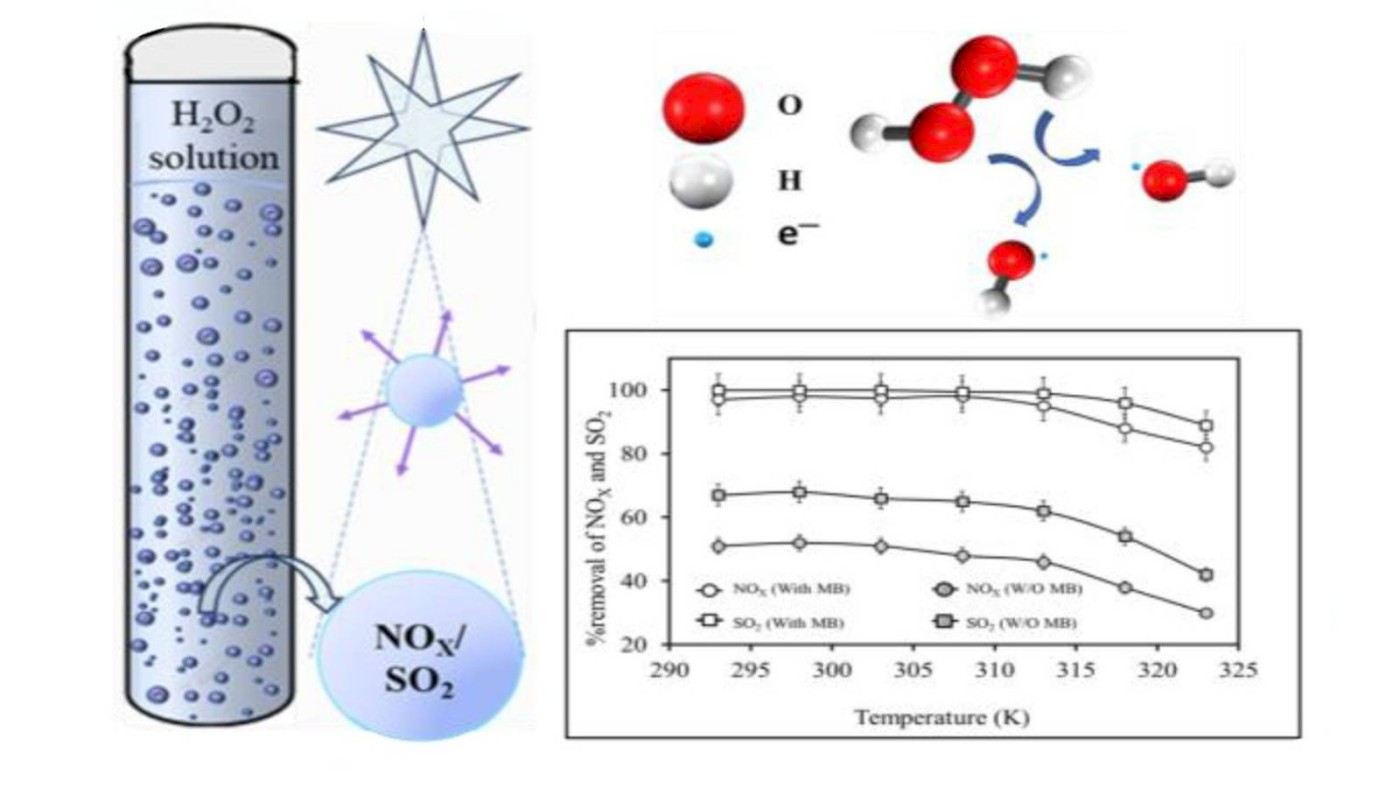

A novel method developed for removing flue gas pollutants has achieved 100 per cent removal of sulphur dioxide (SO2) and over 95 per cent removal of nitrogen oxides (NOx), marking a notable advancement in emission control. The study, helmed by Parveen Dalal, a doctoral student at Ahmedabad University’s School of Engineering and Applied Science, leverages microbubble-assisted oxidation to deliver high-efficiency pollutant removal. Offering a cost-effective and less complex alternative to traditional treatment systems, the study paves the way for cleaner industrial practices

Coal-based power plants, manufacturing, and chemical industries are significant contributors to air pollution through the emission of flue gases, particularly NOx and SO2. Traditional techniques such as Selective Catalytic Reduction (SCR) and Flue Gas Desulphurisation (FGD) often prove to be complex or expensive, especially when aiming for the simultaneous removal of both SO2 and NOx.

The study proposes a cost-effective wet oxidation system that combines microbubbles with hydrogen peroxide (H2O2). It addresses the core challenge of the poor solubility of NOx in water. Unlike conventional approaches that rely on difficult-to-manage oxidants like ozone or UV-activated compounds to convert NOx into soluble nitric acid, this method enhances gas-liquid mass transfer by introducing microbubbles. These tiny (<100 µm), slow-rising bubbles substantially increase the surface area for reaction, improving gas solubility and absorption in water. This innovation makes H2O2 effective as a single oxidant, thereby reducing costs and simplifying the overall process.

The researchers conducted a detailed analysis of mass transfer dynamics and reaction kinetics, examining parameters such as Sauter mean diameter, gas holdup, specific interfacial area, volumetric mass transfer coefficient (kLa), Hatta number, and thermodynamic feasibility.

The study titled A State-of-the-Art Treatment Route of Flue Gases Using Microbubbles was published in Elsevier's journal Chemical Engineering and Processing – Process Intensification. Guided by Professors Snigdha Khuntia and Sridhar Dalai from Ahmedabad University's School of Engineering and Applied Science, the research shows that delivering SO2 and NOx gases into water using microbubbles leads to high removal efficiencies. Importantly, the method does not rely on UV light or co-oxidants, making the process simpler and potentially more scalable for industrial use.