22 December 2024

BTech Students Design Bridge for Landslide-prone Remote Areas

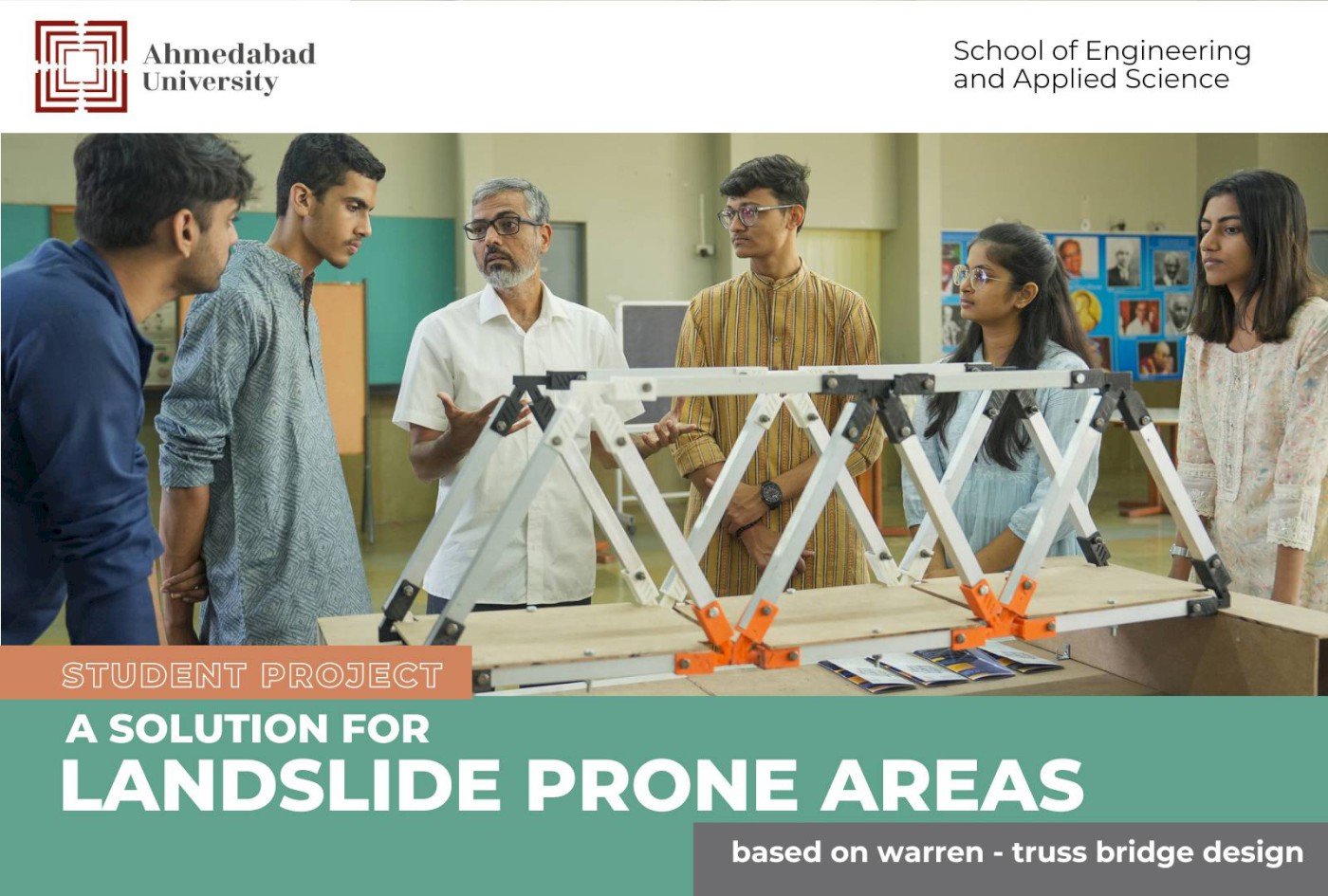

Aimed at enhancing safety measures for people in landslide-prone remote areas, a team of BTech students, including Saumyakumar Jha, Harsh Malodia, Kahan Bhatt, Hiya Shah, Priya Iyengar, and Nirjara Jain, designed and built a prototype of an evacuation Warren truss bridge.

The students designed a 1.2-metre bridge constructed from aluminium rods, adding two glass fibre rods to exhibit the concept. They also developed a design and prototype of a unique locking mechanism.

As part of this project, students learned to define the problem statement, apply poka-yoke and TRIZ analysis, utilise Finite Element Method (FEM) techniques, design the entire bridge, 3D print all connector parts, and incorporate glass fibres and aluminium rods for enhanced strength and durability. They also performed load analysis and gained valuable skills in designing and manufacturing a truss bridge.

This project was designed as part of the Design Innovation and Making course. Offered as part of the Monsoon 2024-2025, the course aims to build a strong theoretical foundation in creativity, innovation, and design thinking while guiding students through structured steps from idea generation to prototype development. Students systematically create novel solutions that meet real-world needs by focusing on customer requirements, detailed design, and product validation.

Experiential learning, such as this, allows students to apply theoretical knowledge to real-world problems, fostering critical thinking and practical skills.